In modern electrical engineering, DC contactors play a critical role in managing and controlling the flow of direct current (DC) in various systems, from electric vehicles and battery banks to industrial automation and renewable energy applications. While often overshadowed by their AC counterparts, DC contactors are essential for ensuring safe, reliable switching in high-load DC circuits.

What is a DC Contactor?

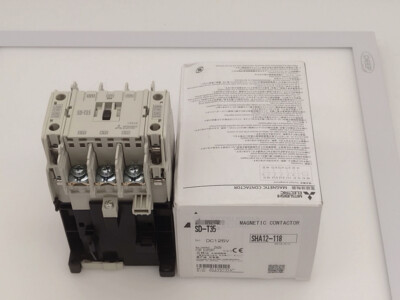

A DC contactor is an electrically controlled switch used to make or break DC power circuits. It works similarly to a relay but is designed to handle higher current loads. Unlike AC contactors that rely on current zero-crossing to interrupt flow, DC contactors must extinguish a constant arc, making their construction more robust and specialized.

These devices are typically composed of:

- Coil (electromagnet): Energizes to move the contacts.

- Contacts: Usually silver-alloy, built to withstand high currents and arc energy.

- Arc chute or blowout magnets: Help extinguish the arc formed during switching.

Where Are DC Contactors Used?

DC contactors are used in a wide range of applications, including:

- Electric vehicles (EVs): Managing battery connections and motor control.

- Solar power systems: Switching battery banks, inverters, or charge controllers.

- Industrial machinery: Controlling motors, actuators, and DC drives.

- Railways and transportation systems: Handling high-voltage traction systems.

- Battery energy storage systems (BESS): Managing load distribution and system safety.

Because of their ability to switch high-voltage and high-current DC circuits quickly and reliably, they are also integral to safety mechanisms, enabling emergency shutdowns or isolating faulty sections.

Key Features and Advantages

- High Voltage and Current Handling:

Designed to handle voltages up to 1000V DC or more and high currents (100A–1000A+), depending on application. - Arc Suppression:

Uses advanced arc-quenching techniques, such as magnetic blowouts and arc chutes, to interrupt the persistent DC arc. - Compact and Durable:

Modern designs ensure minimal space usage while offering long mechanical and electrical life. - Fail-safe Operation:

Many DC contactors are designed to return to a safe state (normally open) when power is lost—crucial for safety-critical systems.

Challenges in DC Switching

Switching DC is inherently more challenging than AC due to the absence of a natural current zero point, which makes arc suppression more difficult. This means:

- Contactors must have superior materials and insulation.

- Contact wear is faster without proper arc management.

- Heat buildup and potential for contact welding are higher.

Proper sizing, ventilation, and using pre-charging circuits can mitigate these issues.

Choosing the Right DC Contactor

When selecting a DC contactor, consider:

- Voltage and current ratings

- Coil voltage (12V, 24V, etc.)

- Mounting style (panel, DIN rail)

- Environment (temperature, vibration, moisture)

- Arc suppression method

Brands like Schneider Electric, Eaton, Tyco Electronics, and Kisens offer specialized contactors for EVs, solar, and industrial sectors.

Conclusion

As the world shifts toward electrification and renewable energy, DC contactors are becoming more critical than ever. Whether managing battery systems, electric drives, or safety circuits, they provide the control and reliability required in today’s energy landscape.

Understanding how they work, where they’re used, and what to look for can help engineers, technicians, and energy professionals ensure safer and more efficient operations.