The textile industry has always played a vital role in shaping fashion and lifestyle trends worldwide. But with increasing awareness of climate change and resource depletion, sustainability has become a central focus. One of the most promising innovations in this regard is recycled yarn—an eco-friendly alternative to conventional yarn. While traditional yarn relies heavily on virgin resources like cotton and petroleum-based fibers, recycled yarn is created from post-consumer waste, textile scraps, and discarded plastics.

In this blog, we’ll explore the environmental impact of recycled yarn vs. conventional yarn, and why working with reliable recycled yarn manufacturers and suppliers is essential for building a sustainable future in textiles.

Understanding Conventional Yarn

Conventional yarn typically comes from two major sources:

-

Natural Fibers (e.g., cotton, wool, silk)

-

Requires large amounts of land, water, and pesticides (especially in cotton production).

-

Cotton farming alone consumes about 10,000 liters of water per kilogram of fiber.

-

-

Synthetic Fibers (e.g., polyester, nylon, acrylic)

-

Derived from petroleum-based resources.

-

Energy-intensive production processes that release greenhouse gases.

-

Non-biodegradable, contributing to long-term microplastic pollution in oceans.

-

The reliance on virgin resources and the waste generated at the end of a product’s life cycle make conventional yarn less sustainable in the long run.

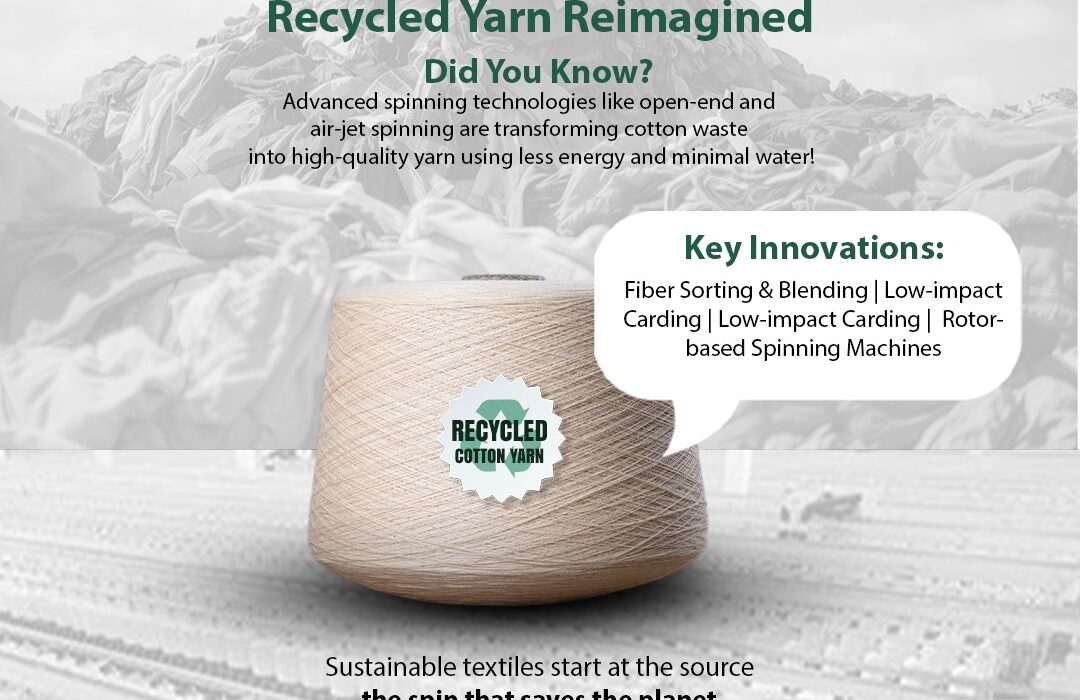

What is Recycled Yarn?

Recycled yarn is produced by reprocessing textile waste, industrial fabric scraps, or used plastic bottles into fibers and then spinning them into yarn. Depending on the source material, recycled yarn can be made from:

-

Recycled Cotton – from pre-consumer textile scraps.

-

Recycled Polyester (rPET) – from PET plastic bottles.

-

Blended Recycled Yarns – a mix of recycled and virgin fibers for durability.

Trusted recycled yarn manufacturers and suppliers ensure that this process meets global sustainability standards, often certified by organizations like GRS (Global Recycled Standard) or OEKO-TEX.

Environmental Impact: Recycled Yarn vs. Conventional Yarn

Let’s break down the environmental impact into key categories:

1. Water Consumption

-

Conventional Cotton Yarn: Cotton farming consumes massive amounts of fresh water and contributes to water scarcity in agricultural regions.

-

Recycled Yarn: Uses 90–95% less water because it relies on pre-existing fibers instead of growing new crops.

✅ Winner: Recycled Yarn

2. Energy Use & Carbon Emissions

-

Conventional Synthetic Yarn: Petroleum-based yarns like polyester require high energy input and release large amounts of CO₂.

-

Recycled Yarn (rPET): Produces up to 50% fewer greenhouse gas emissions compared to virgin polyester.

✅ Winner: Recycled Yarn

3. Waste Management

-

Conventional Yarn: Generates textile waste during production and contributes to landfill problems after disposal.

-

Recycled Yarn: Reduces textile and plastic waste by turning discarded materials into usable products, aligning with the circular economy model.

✅ Winner: Recycled Yarn

4. Soil & Land Use

-

Conventional Cotton Yarn: Requires extensive land for farming and often depletes soil nutrients due to monocropping.

-

Recycled Yarn: Doesn’t require farmland, reducing pressure on ecosystems and preventing deforestation.

✅ Winner: Recycled Yarn

5. Microplastic Pollution

-

Conventional Synthetic Yarn: Polyester sheds microplastics during washing, polluting oceans.

-

Recycled Polyester Yarn: While it still sheds microplastics, recycling reduces the initial plastic waste burden. Many recycled yarn manufacturers are also working on innovations to minimize shedding.

The Bigger Picture: Sustainability Benefits

-

Resource Conservation – Saves water, energy, and raw materials.

-

Waste Reduction – Diverts millions of tons of textile waste and plastic from landfills.

-

Circular Economy Model – Promotes reuse and recycling instead of linear consumption.

-

Eco-Friendly Branding – Helps businesses align with global sustainability goals and eco-conscious consumers.

Why Choose Trusted Recycled Yarn Manufacturers & Suppliers?

Not all recycled yarn is created equal. The quality, consistency, and certifications depend heavily on the manufacturer’s process. Reliable recycled yarn suppliers ensure:

-

Certifications (GRS, OEKO-TEX, ISO).

-

Consistent Quality that matches virgin yarn performance.

-

Customization (blends, colors, counts, finishes).

-

Sustainability Tracking (proof of reduced carbon and water footprint).

Partnering with reputable recycled yarn manufacturers allows brands to maintain product quality while making a genuine commitment to sustainability.

Challenges of Recycled Yarn

While recycled yarn is far more sustainable, it’s not without challenges:

-

Durability Issues – Recycled fibers may be shorter, reducing strength compared to virgin fibers.

-

Limited Color Options – Pre-dyed textile waste can limit shade accuracy.

-

Higher Costs – Some recycled yarns may be costlier due to specialized processes.

However, ongoing innovations by leading recycled yarn suppliers are steadily overcoming these barriers.

Future of Recycled Yarn

With global fashion giants and textile brands adopting sustainable practices, demand for recycled yarn is growing rapidly. Advanced recycling technologies—like chemical recycling for polyester and mechanical recycling for cotton—are making recycled yarn almost indistinguishable from virgin yarn.

In the future, recycled yarn manufacturers will play a crucial role in building a truly circular textile economy where waste becomes raw material.

Conclusion

When comparing the environmental impact of recycled yarn vs. conventional yarn, the results are clear: recycled yarn is the more sustainable choice. By conserving water, reducing carbon emissions, and minimizing waste, recycled yarn helps protect the environment while supporting the textile industry’s future.

For fashion brands, textile businesses, and consumers alike, partnering with recycled yarn suppliers is more than just an eco-friendly choice—it’s an investment in a greener tomorrow.