The Ethylene Oxide Market encompasses the global production, distribution, and application of ethylene oxide (EO), a highly reactive chemical compound used primarily as an intermediate in producing a wide range of consumer and industrial goods. Ethylene oxide is a colorless, flammable gas with a faintly sweet odor, primarily utilized to manufacture ethylene glycol, surfactants, detergents, polyethylene glycols, and glycol ethers. It also serves as a sterilizing agent in medical and pharmaceutical industries.

The global importance of ethylene oxide lies in its central role as a key chemical feedstock for several downstream industries, including textiles, packaging, automotive, pharmaceuticals, and personal care. Demand for EO and its derivatives is driven by global industrialization, rising consumer goods production, and expanding healthcare sterilization needs.

As of 2025, the ethylene oxide market is estimated to be valued at USD 35 billion, with projections suggesting it will reach approximately USD 50 billion by 2035, growing at a compound annual growth rate (CAGR) of around 3.7%. The expansion of downstream applications such as antifreeze, polyester fibers, and sterilization products continues to support long-term market growth and resilience.

Learn how the Ethylene Oxide Market is evolving—insights, trends, and opportunities await. Download report: https://www.databridgemarketresearch.com/reports/global-ethylene-oxide-market

The Evolution

The evolution of the ethylene oxide market began in the early 20th century with the discovery of EO’s synthesis from ethylene and oxygen. Initially, the compound found limited use due to its flammable nature and toxicity. The large-scale industrial production of ethylene oxide began after the 1930s when safer catalytic oxidation methods were developed, particularly using silver-based catalysts.

During the 1950s and 1960s, EO became one of the most significant building blocks in the petrochemical industry. The expansion of ethylene production capacities, primarily through steam cracking, fueled a corresponding increase in EO output. Key milestones included the development of efficient oxidation reactors, process automation, and closed-loop systems that reduced emission risks.

By the late 20th century, ethylene oxide emerged as a cornerstone in the production of ethylene glycols used in antifreeze, polyester fibers, and PET resins. The 21st century introduced more sustainable and energy-efficient EO manufacturing technologies. Companies invested in process optimization to improve yield and minimize hazardous byproducts such as ethylene chlorohydrin.

Recent developments include the adoption of continuous catalytic oxidation processes, advanced leak detection systems, and integration with carbon capture technologies to minimize greenhouse gas emissions. These innovations have significantly enhanced production safety and efficiency, aligning the industry with global environmental standards.

Market Trends

Emerging trends in the ethylene oxide market reflect technological advancement, environmental compliance, and diversified end-use demand.

-

Rising demand for ethylene glycols: Ethylene glycol remains the largest application of EO, used in the production of antifreeze, polyester fibers, and polyethylene terephthalate (PET) bottles. Increasing consumption in textile and packaging industries continues to boost this segment.

-

Shift toward sustainable and low-emission production: Manufacturers are investing in cleaner technologies, including catalytic oxidation processes that lower energy consumption and emissions. The development of bio-based ethylene feedstock is gaining attention as companies aim to reduce carbon footprints.

-

Growing healthcare and sterilization applications: EO’s unique ability to sterilize heat-sensitive medical equipment drives its growing use in hospitals, pharmaceutical facilities, and laboratories. The healthcare sterilization segment is expected to expand as global medical infrastructure improves.

-

Regional capacity expansion: Asia-Pacific continues to dominate EO production due to cost advantages and abundant feedstock. China, India, and South Korea are expanding capacity to meet both domestic and export demand.

-

Integration with downstream industries: Many producers are integrating EO plants with ethylene and glycol production units to optimize resource use and enhance operational efficiency.

Global adoption patterns reveal that while developed markets focus on sustainability and process optimization, developing regions prioritize capacity expansion to meet growing industrial and consumer demands.

Challenges

The ethylene oxide market faces several regulatory, economic, and supply chain challenges.

Regulatory pressures present one of the most significant constraints. Ethylene oxide is classified as a hazardous chemical due to its toxicity, flammability, and carcinogenic properties. Governments have imposed strict regulations on production, storage, and transportation. Compliance with safety and environmental standards increases production costs and limits expansion in certain regions.

Economic challenges include fluctuating raw material costs and dependence on ethylene derived from crude oil or natural gas. Volatile energy prices affect production economics and profitability. The global transition toward renewable energy and bio-based feedstocks presents both challenges and opportunities for EO manufacturers.

Supply chain complexities stem from the need for specialized infrastructure. Ethylene oxide requires controlled environments for storage and transport due to its explosive nature. Limited logistics infrastructure in developing economies can delay supply and affect downstream industries.

Barriers to growth include public health concerns related to EO emissions and exposure. Communities near EO production facilities often express opposition, leading to stricter local regulations or plant closures.

Risks also include operational hazards such as accidental releases, fires, or explosions, which can disrupt production and damage public perception. In addition, competition from alternative sterilization technologies, such as vaporized hydrogen peroxide and gamma irradiation, may limit growth in specific applications.

Market Scope

The ethylene oxide market is broad and categorized by type, application, and end-user industries.

By Type

-

Ethylene Glycol (Monoethylene Glycol, Diethylene Glycol, Triethylene Glycol)

-

Ethanolamines

-

Ethoxylates

-

Polyethylene Glycols

-

Glycol Ethers

-

Ethylene Carbonate

-

Others

By Application

-

Antifreeze and Coolants

-

Polyester Fibers and Resins

-

Detergents and Surfactants

-

Solvents and Lubricants

-

Sterilization of Medical Equipment

-

Chemical Intermediates

By End-User Industry

-

Automotive

-

Packaging

-

Textile

-

Healthcare

-

Chemicals

-

Construction

-

Personal Care and Cosmetics

Regional Analysis

-

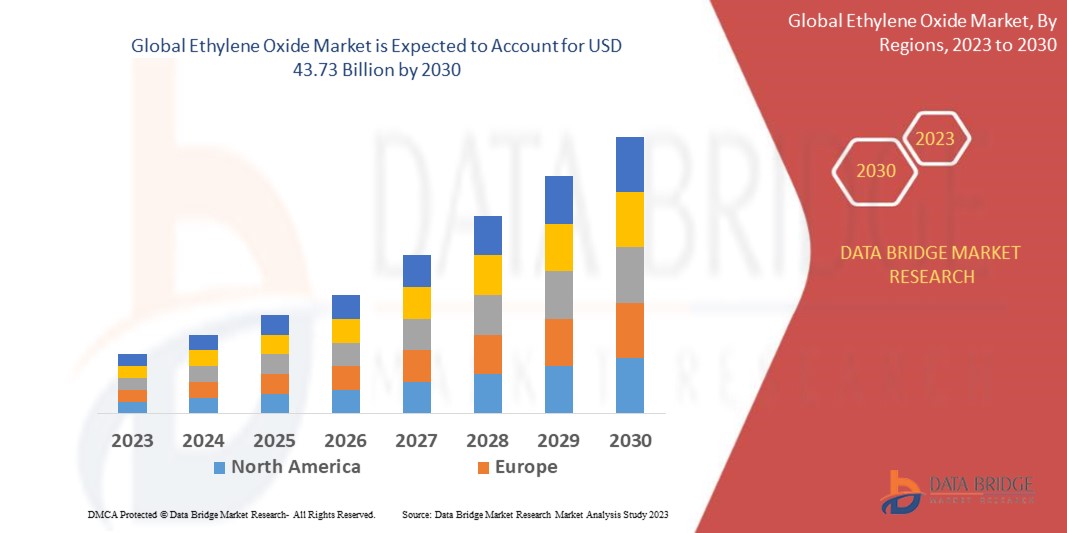

North America: Mature market characterized by strict environmental regulations and established industrial infrastructure. Growth focuses on process innovation and emissions reduction.

-

Europe: Increasing regulatory pressure drives investment in sustainable production technologies and circular economy initiatives.

-

Asia-Pacific: Largest and fastest-growing regional market, led by China and India. Industrial expansion, urbanization, and export-oriented manufacturing fuel demand.

-

Latin America: Moderate growth driven by infrastructure development and rising consumer goods production in Brazil and Mexico.

-

Middle East & Africa: Emerging market with potential growth from expanding petrochemical facilities and government diversification initiatives.

Market Size and Factors Driving Growth

Data Bridge Market Research analyses that the ethylene oxide market which was USD 32.78 billion in 2022, will reach USD 43.73 billion by 2030, and is expected to undergo a CAGR of 3.67% during the forecast period.

Key factors driving growth include:

-

Industrial expansion and consumer goods demand

Ethylene oxide derivatives are critical to producing polyester fibers, PET packaging, detergents, and coolants—sectors expanding with global industrialization and urban population growth. -

Healthcare sterilization demand

The increasing need for sterilized medical equipment and pharmaceutical products fuels EO consumption in sterilization facilities worldwide. -

Technological advancements

Innovations in catalytic oxidation and leak detection improve process efficiency and reduce emissions, making EO production safer and more sustainable. -

Automotive and packaging industries

Rising production of vehicles and plastic packaging increases the demand for ethylene glycol-based products. -

Population and lifestyle shifts

Growing middle-class populations and consumer spending drive demand for personal care products, textiles, and packaged goods—all of which rely on EO derivatives. -

Policy and sustainability focus

Governments promoting energy-efficient and eco-friendly production are encouraging the adoption of cleaner EO manufacturing technologies.

Opportunities in emerging regions are expanding rapidly. The Asia-Pacific region is projected to account for more than half of global EO demand by 2035, driven by industrial growth, favorable policies, and lower feedstock costs. Latin America and the Middle East also present opportunities due to increasing investments in petrochemical complexes and infrastructure modernization.

Conclusion

The ethylene oxide market remains a cornerstone of the global chemical industry. It serves as a critical intermediate in producing a wide array of industrial and consumer products. Growth through 2035 will be sustained by expanding demand in textiles, automotive, packaging, and healthcare sectors.

Innovation and sustainability will define the market’s future. Investment in safer, energy-efficient production technologies and bio-based feedstocks will enhance competitiveness and ensure long-term viability. As environmental and safety standards become stricter, the industry’s focus will continue shifting toward cleaner production and circular economy solutions.

For stakeholders—manufacturers, investors, and policymakers—the ethylene oxide market offers opportunities in capacity expansion, sustainable technology integration, and new applications aligned with global industrial transformation.

FAQ

Q1. What is ethylene oxide used for?

Ethylene oxide is primarily used as a chemical intermediate to produce ethylene glycol, surfactants, ethanolamines, and other derivatives. It is also used as a sterilizing agent for medical and pharmaceutical products.

Q2. What is the current size of the ethylene oxide market?

As of 2025, the ethylene oxide market is valued at approximately USD 35 billion and is projected to reach around USD 50 billion by 2035.

Q3. Which industries are the main consumers of ethylene oxide?

Major industries include automotive, textile, packaging, healthcare, and chemicals. These sectors use EO derivatives for antifreeze, polyester fibers, plastics, and sterilization processes.

Q4. What factors are driving the growth of the ethylene oxide market?

Key drivers include increasing demand for ethylene glycol, growth in healthcare sterilization, expanding packaging and textile industries, and advancements in sustainable manufacturing technologies.

Q5. Which region dominates the global ethylene oxide market?

The Asia-Pacific region leads global production and consumption, driven by industrial expansion, population growth, and low feedstock costs.

Q6. What challenges does the market face?

Major challenges include regulatory restrictions, safety concerns, emission control requirements, and competition from alternative sterilization technologies.

Q7. What is the expected CAGR of the ethylene oxide market through 2035?

The ethylene oxide market is expected to grow at a CAGR of approximately 3.7% during the forecast period.

Browse More Reports:

North America Edible Oil Market

Europe Electric Vehicle Heat Shrink Tubing Market

Asia-Pacific Electric Vehicle Heat Shrink Tubing Market

Middle East and Africa Electric Vehicle Heat Shrink Tubing Market

North America Electric Vehicle Heat Shrink Tubing Market

Mexico Electron Microscope Market

Asia-Pacific Electrophysiology Mapping and Ablation Devices Market

Middle East and Africa Endoscopic Retrograde Cholangiopancreatography Devices Market

Asia-Pacific Endoscopic Retrograde Cholangiopancreatography Devices Market

Europe Endoscopic Retrograde Cholangiopancreatography Devices Market

North America Endoscopic Retrograde Cholangiopancreatography Devices Market

Europe Epigenetics Diagnostic Market

North America Epigenetics Diagnostic Market

Asia-Pacific Epigenetics Diagnostic Market

Middle East and Africa Epigenetics Diagnostic Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com