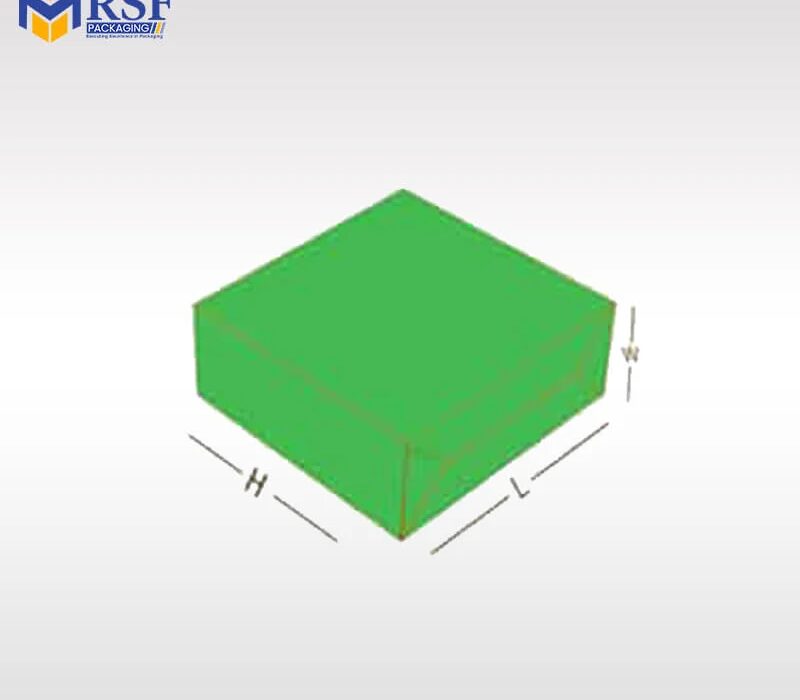

When it comes to packaging that offers both strength and convenience, the Full Flap Auto Bottom box stands out as one of the most reliable solutions. Its design combines an auto-lock bottom with extended flaps, giving extra durability for products that need maximum protection during storage, shipping, or retail display.

Unlike regular tuck or snap-lock boxes, this style is built for heavy or fragile products. The base forms automatically when folded, saving time during assembly. The long flaps reinforce the structure, ensuring products stay safe. For businesses in the USA, this makes Full Flap Auto Bottom boxes an excellent choice for packaging that is both secure and practical.

Suppliers like rsfpackaging provide fully customizable Full Flap Auto Bottom boxes in a variety of sizes, materials, and finishes, helping brands deliver products safely while showcasing strong branding.

Why Choose Full Flap Auto Bottom Boxes?

Businesses across industries prefer this box style for its unique combination of strength and efficiency. Standard auto bottom boxes are already sturdy, but the addition of full flaps makes them even more reliable. This is especially important for products like glassware, electronics, cosmetics, or food jars.

Another advantage is quick assembly. The auto-lock base pops into place, reducing packing time compared to manually glued or taped boxes. This makes it ideal for large-scale production lines. At the same time, its flat shipping design saves space and reduces transportation costs.

In short, Full Flap Auto Bottom packaging provides peace of mind for businesses and convenience for workers, all while looking professional on retail shelves.

Features and Benefits

The Full Flap Auto Bottom box is designed with both functionality and presentation in mind. Some of its biggest benefits include:

-

Reinforced strength from extended flaps that lock securely.

-

Quick setup with auto bottom design for fast assembly.

-

Versatility suitable for retail, shipping, and e-commerce.

-

Custom branding with large printable surfaces for logos and designs.

-

Flat shipping reduces storage needs and delivery costs.

These features make it one of the most practical packaging styles for businesses needing strength without sacrificing style.

Common Uses in the USA

Full Flap Auto Bottom boxes are popular across different industries thanks to their durability. Some common uses include:

-

Food and Beverage Packaging – Bottled drinks, glass jars, sauces, or other fragile items.

-

Cosmetics and Skincare – Perfume bottles, creams, and delicate beauty products.

-

Electronics – Gadgets, mobile accessories, and fragile tech products.

-

Retail Packaging – Items requiring both strength and attractive presentation.

-

E-commerce – Secure delivery of heavier products without damage.

This versatility makes the box style a dependable choice for both small businesses and large retailers.

Materials and Customization Options

The choice of material plays a big role in the performance of a Full Flap Auto Bottom box. Common options include:

-

Cardstock – Lightweight but strong, perfect for cosmetics and retail.

-

Kraft Paper – Eco-friendly, recyclable, and durable for sustainable packaging.

-

Corrugated Board – Extra strength for shipping heavy or fragile goods.

Printing options are also extensive. Brands can use CMYK full-color printing, spot UV, foil stamping, embossing, or matte/gloss finishes to match their product’s style. Providers like rsfpackaging help businesses design packaging that reflects their brand identity while staying functional.

Easy Assembly for Businesses

One of the biggest reasons businesses choose this packaging is how easy it is to assemble. Workers don’t have to spend time gluing or taping. The auto-lock base folds automatically, and the full flaps add strength instantly. For high-volume production lines, this can save hours of labor and reduce errors in packaging.

Flat shipping also helps reduce storage costs. Businesses can order bulk boxes without worrying about space, as they are only folded when needed.

Eco-Friendly Options

Sustainability is becoming a top priority in packaging. Full Flap Auto Bottom boxes can be made from recyclable kraft or biodegradable materials, offering eco-friendly choices without sacrificing strength. Many USA businesses now prefer eco-conscious options to appeal to environmentally aware customers.

By choosing recyclable packaging, brands show responsibility while reducing their carbon footprint—a factor that also improves brand reputation.

FAQs About Full Flap Auto Bottom Boxes

Q1: What products are best suited for Full Flap Auto Bottom boxes?

They are ideal for heavy, fragile, or high-value products like glass, electronics, or cosmetics.

Q2: Are they more secure than regular auto bottom boxes?

Yes. The full flaps add extra reinforcement, making them stronger than standard designs.

Q3: Can these boxes be customized with branding?

Yes. They offer large printable areas for custom designs, logos, and colors.

Q4: Are eco-friendly versions available?

Yes. They can be made from recyclable or biodegradable materials.

Final Thoughts

The Full Flap Auto Bottom box is a trusted packaging style for businesses that need security, convenience, and professional presentation. Its auto-lock design saves time, while the reinforced flaps provide the strength needed for fragile or heavy products.

For companies in the USA, choosing this packaging style means better product protection, cost savings on labor and logistics, and improved brand presentation. With custom designs from suppliers like rsfpackaging, these boxes can match your product’s identity while keeping it safe.